Pratt & Whitney: Pioneering Sustainable Aviation

With a legacy of groundbreaking innovations in aircraft propulsion spanning over ninety years, P&W continues to drive the industry towards a net-zero aviation CO2 emissions future by 2050

In an era where environmental sustainability is paramount, the aerospace industry faces the dual challenge of meeting growing demands for air travel while reducing its ecological footprint. As companies continue to take significant initiatives, Pratt & Whitney is among the leaders of this endeavour. Through innovative technology, greener business practices, and a steadfast commitment to environmental stewardship, Pratt & Whitney (P&W) is shaping the future of flight with a focus on sustainability through smarter technology, revolutionising and maximising efficiency. With a legacy of groundbreaking innovations in aircraft propulsion spanning over ninety years, P&W continues to drive the industry towards a net-zero aviation CO2 emissions future by 2050.

THE GTF ADVANTAGE

Pratt & Whitney leads in efficient singleaisle aircraft engines, investing in advanced technology like the gamechanging GTF engine introduced in 2016. Pratt & Whitney’s Geared Turbofan (GTF) engine, backed by over $10 billion in investment, has been a game-changer, delivering up to a 20 per cent improvement in fuel efficiency for single-aisle aircraft while significantly reducing NOx emissions and noise footprint. This technology has already made air travel more sustainable, saving millions of tonnes of CO2 emissions. The progress with the GTF Advantage marks the initial stride towards future propulsion systems aligned with aviation’s net-zero carbon emissions goal by 2050.

Collaborating with industry partners, P&W is working towards enabling the use of 100 per cent SAF in the future

The Pratt & Whitney GTF Advantage engine for Airbus A320neo family aircraft takes efficiency to the next level, offering an additional one per cent improvement in fuel burn and CO2 emissions alongside greater thrust. This evolution demonstrates P&W’s commitment to advancing GTF architecture for large transport aircraft.

TURBOPROP EFFICIENCY

The PW127XT-M engine for ATR 42/72 aircraft also sets new benchmarks in performance. With three per cent better fuel efficiency and lower CO2 emissions, along with reduced maintenance costs and extended time on wing, the turboprop engines offer unparalleled sustainability advantages.

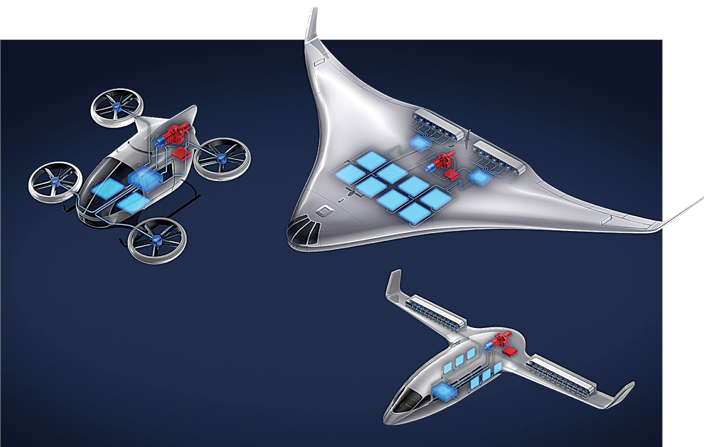

HYBRID-ELECTRIC PROPULSION

Pratt & Whitney Canada is at the forefront of hybrid-electric propulsion technology, aiming for a 30 per cent improvement in fuel efficiency with its regional aircraft demonstrator. Developed in collaboration with Collins Aerospace and De Havilland Aircraft of Canada, this initiative aims at optimising performance and reducing environmental impact in the future of aviation. Collaborative projects like SWITCH and STEP-Tech are developing hybrid electric propulsion systems for even greater efficiency gains, with potential CO2 emission reductions.

CLEANER FUEL

The transition to cleaner fuels emerges as a pivotal step towards achieving a net-zero future for civil aviation. Pratt & Whitney continues to develop smarter technologies to aid this transition, advancing the use of Sustainable Aviation Fuels (SAF) and pioneering technologies to support alternative, zero-carbon fuels like hydrogen.

SAF-READY

Pratt & Whitney engines are primed to operate with SAF blends of up to 50 per cent with Standard Jet A Kerosene. These stand on the strong base of P&W’s role in defining technical standards for SAF blends and their involvement in SAF testing and certification that spans decades. Collaborating with industry partners, P&W is working towards enabling the use of 100 per cent SAF in the future, ensuring compatibility with nextgeneration engines like the GTF Advantage.

HARNESSING HYDROGEN POWER

Hydrogen, with its energy-rich and carbon-free properties, holds immense potential for enabling zero-emissions flight. Despite challenges, P&W believes that their extensive expertise in hydrogen-fueled propulsion systems position them well to navigate this frontier. The Hydrogen Steam-Injected, Inter-Cooled Turbine Engine (HySIITE) project embodies P&W’s commitment to innovation in hydrogen-fueled propulsion. By optimising engine design to leverage the unique cryogenic properties of hydrogen, HySIITE aims to achieve zero in-flight CO2 emissions, an 80 per cent reduction in nitrogen oxide emissions, and up to a 35 per cent decrease in fuel consumption for next-generation single-aisle aircraft.

ADVANCED TECHNOLOGIES

Revolutionary materials like Ceramic Matrix Composites (CMCs) are enhancing engine efficiency by withstanding higher temperatures and reducing fuel consumption. Electrification efforts, such as the Scalable Turboelectric Powertrain Technology (STEP-Tech) demonstrator, offer complete or partial electrification solutions for aircraft of various sizes. Hybrid-electric propulsion (HEP) technology, demonstrated in a modified De Havilland Canada Dash 8-100 regional jet, promises up to 30 per cent fuel burn reduction compared to existing turboprops.

GREENER BUSINESS PRACTICES

While Pratt & Whitney remains dedicated to advancing sustainable aviation through innovative propulsion technology, the company equally prioritises reducing its environmental impact through greener business practices including:

- 2025 Environment, Health & Safety Goals: Pratt & Whitney’s commitment to sustainability includes energy efficiency enhancements, expanding renewable energy usage, and minimising landfill waste and water consumption. Since 2006, the company has significantly reduced greenhouse gas emissions, increased waste recycling, and achieved double-digit reductions in annual water usage.

- Industry 4.0 Transformation: Embracing the principles of Industry 4.0, Pratt & Whitney is modernising its global manufacturing operations to enhance efficiency and sustainability. Through investments in connected factories, automation, and advanced process control, the company is driving improvements in manufacturing effectiveness while reducing environmental impact.

- Exemplary Facilities: Pratt & Whitney’s new airfoil production facility in Asheville, North Carolina, exemplifies its modernisation efforts. This state-of-the-art, vertically integrated facility utilises highly automated processes to streamline production, reducing transportation distances and handoffs while enhancing efficiency.

- LEED Certified Buildings: Pratt & Whitney boasts 14 LEED Silver or better certified buildings globally, demonstrating its commitment to sustainable building practices across its operations.

- Green Factory Forums: Pratt & Whitney fosters knowledge-sharing and innovation through Green Factory Forums, where manufacturing facilities exchange best practices in sustainability, from utility management to waste reduction.

- Best Management Practices: Pratt & Whitney and Raytheon Technologies have implemented Best Management Practices (BMPs) to guide facilities in waste management, recycling, and environmental stewardship, ensuring alignment with shared sustainability goals.

- Social Initiatives: Committed to supporting both the environment and communities, Pratt & Whitney integrates key social initiatives into its programmes, leveraging its industry position for positive societal impact.

- Materials of Concern Reduction: Pratt & Whitney’s Green Engine Programme, initiated in the 1990s, has been instrumental in minimising Materials of Concern (MOC) in engine design, manufacturing, and maintenance. The company continues to invest in green technologies, including those of its suppliers, to further reduce environmental impact.

RECENT UPDATES TOWARDS THE SUSTAINABLE ROUTE

IAE tests V2500 engine: IAE International Aero Engines AG (IAE), a consortium including Pratt & Whitney, successfully tested the V2500 engine with 100 per cent SAF at MTU Maintenance Hannover, Germany. The engine powers A320ceo family aircraft and the Embraer C-390 Millennium, offering fuel efficiency and emissions advantages. The test used Hydroprocessed Esters and Fatty Acids Synthetic Paraffinic Kerosine (HEFA-SPK) fuel supplied by Neste, a sustainable alternative to conventional jet fuels. Pratt & Whitney collaborated with CAAFI and ASTM International to develop specifications for 100 per cent SAF.

HySIITE aims to achieve zero in-flight CO2 emissions, an 80 per cent reduction in nitrogen oxide emissions, and up to a 35 per cent decrease in fuel consumption for nextgeneration single-aisle aircraft

Greener operations: Pratt & Whitney’s emphasis on sustainability in its operations is evident in new facilities in Carlsbad, California, and Asheville, North Carolina. The Asheville site, featuring advanced casting foundry and airfoil production, exceeds goals for greenhouse gas, water, and waste reduction. Carlsbad focuses on reducing its carbon footprint with on-site heat reclamation and power generation. As part of Raytheon Technologies, Pratt & Whitney sets EH&S goals to reduce emissions, water usage, and waste. Collaboration and innovation drive their commitment to a smarter, cleaner, and greener aviation future.

SAF shift & Hydrogen hike: Pratt & Whitney supports the shift to cleaner fuels like SAF. All engines are SAF-compatible up to 50 per cent, with plans for 100 per cent SAF readiness. Recent tests, including with the GTF Advantage engine, demonstrate progress in this area. Additionally, Pratt & Whitney is pioneering hydrogen propulsion technology through projects like HySIITE, aiming for zero CO2 emissions and significant fuel consumption reduction. Despite infrastructure challenges, Pratt & Whitney remains committed to advancing sustainable aviation solutions. Pratt & Whitney is also pioneering hydrogen propulsion, with decades of experience in hydrogen-burning turbine engines.

THE PATH AHEAD

Pratt & Whitney is at the forefront of sustainable flight, advancing engine technologies and fuel efficiencies to meet the goal of net-zero CO2 emissions by 2050. Pratt & Whitney is investing in technology programmes as well as people to achieve these goals.

Collaborative projects like SWITCH and STEP-Tech are developing hybrid electric propulsion systems for even greater efficiency gains, with potential CO2 emission reductions

The scalable geared architecture has laid the groundwork for future propulsion systems, exemplified by ongoing efforts such as the GTF Advantage. The progress with the GTF Advantage marks the initial stride towards future propulsion systems aligned with aviation’s net-zero carbon emissions goal by 2050. Collaborating with Collins Aerospace, Pratt & Whitney is pioneering sustainable solutions for regional aircraft, including the RTX hybrid-electric flight demonstrator programme. While hybrid-electric propulsion is in early stages, it holds promise for achieving net-zero carbon emissions by 2050, alongside advancements in battery technology and sustainable aviation fuels. Within RTX, Pratt & Whitney and Collins Aerospace have collaborated on sustainable solutions tailored for regional aircraft, including hybrid-electric propulsion technology and a flight demonstrator programme. A significant milestone was achieved with last year’s successful rated power test of the demonstrator’s 1-megawatt electric motor developed by Collins. This motor, coupled with a highly efficient thermal engine from Pratt & Whitney, aims to showcase a 30 per cent improvement in fuel efficiency and CO2 emissions over current regional turboprops.

When it comes to India, Pratt & Whitney is confident that India’s industry and technology will play a crucial role in shaping this sustainable flight future, driving Pratt & Whitney’s continued success through increased investments and collaboration. Testing for unprecedented performance levels is underway, with expectations of its appeal in the Indian market. P&W’s impact in India transcends powering over 600 aircraft, encompassing advancements in aerospace and defence through investments in engineering, training, supply chain, digital capabilities, and innovation.

As Pratt & Whitney continues to lead the charge towards a more sustainable aviation future, its efforts serve as a beacon of hope for the entire aerospace industry. By prioritising smarter technology, cleaner fuels, and greener business practices, Pratt & Whitney is constantly aiming to transform the way we fly while also ensuring a healthier planet for future generations.