Sustainable Aviation — An Important Goal

Amidst growing concerns over environmental impact, leading OEMs across the aviation sector are dedicated to developing sustainable solutions to chart a course towards a cleaner, more sustainable future for air travel

The imperative for the commercial aviation sector to embrace sustainability has reached new heights. While currently responsible for a modest 2.4 per cent of global carbon dioxide (CO2) emissions, its share is poised to triple by 2050 amid burgeoning traffic and advancements in decarbonisation across other sectors. The industry’s pledge to achieve net-zero carbon emissions by 2050 demands significant strides in sustainable aviation fuels (SAF) and the adoption of more fuel-efficient aircraft. Despite projections of rapid SAF production growth, its high cost and current utilisation at a mere one percent of global jet fuel consumption underscore the challenges ahead. Dominated by key players such as Airbus and Boeing, alongside engine manufacturers General Electric Aerospace (GE), CFM, Pratt & Whitney, and Rolls-Royce, the industry is witnessing concerted efforts to enhance fuel efficiency through innovative technologies. As a pivotal force for global connectivity and economic vitality, the aerospace sector is poised to spearhead the transition towards a carbon-neutral future, with these leading aviation OEMs standing fast in their commitment to lead this transformative journey.

BOEING’S LEADERSHIP IN AVIATION SUSTAINABILITY

At the forefront of aerospace innovation, Boeing spearheads sustainable solutions, anchoring its strategy on four pillars: fleet modernisation, renewable energy adoption, advanced technologies, and operational efficiency.

Boeing’s latest aircraft iterations signify substantial leaps in fuel efficiency. The 737 MAX, for instance, reduces fuel consumption and emissions by 20 per cent, enabling airlines to extend routes and payloads while minimising environmental impact. Similarly, the 787 Dreamliner boasts a remarkable 25 per cent enhancement in fuel efficiency, making it a preferred choice for environmentally conscious airlines.

Boeing recognises the pivotal role of Sustainable Aviation Fuel (SAF) in achieving net-zero emissions by 2050. Derived from renewable sources, SAF significantly slashes lifecycle carbon emissions. Boeing actively collaborates with fuel suppliers to ensure compatibility with existing aircraft, while supporting the development of SAF standards for broader adoption.

Innovation drives Boeing’s exploration of alternative propulsion systems. Electric and hybrid-electric systems show promise, particularly for short-range flights. Through partnerships like the Electric Powertrain Flight Demonstration programme with Aurora, Boeing aims to integrate megawatt-class electric propulsion systems into actual aircraft. Additionally, Boeing explores hydrogen fuel cells, leveraging its expertise in space technology for potential application in commercial aviation.

Boeing recognises that operational efficiency is pivotal in reducing emissions. Collaborating with air traffic control agencies globally, Boeing optimises flight paths to minimise fuel consumption. Initiatives like the ecoDemonstrator programme test innovative technologies such as sustainable cabin materials and fibre optic fuel sensors compatible with SAF.

Boeing acknowledges that a sustainable future demands collective action. Through forums like the Sustainable Aerospace Together Forum, Boeing collaborates with stakeholders to develop solutions. Tools like Cascade facilitate data-driven decision-making, empowering stakeholders to maximise sustainability efforts.

While SAF remains a frontrunner for decarbonisation, Boeing invests in electric, hydrogen, and advanced aircraft designs like the Transonic Truss-Braced Wing (TTBW). Recent acquisitions like Wisk Aero highlight Boeing’s commitment to exploring diverse avenues towards sustainability.

AIRBUS: CHARTING THE COURSE FOR SUSTAINABLE AVIATION

As a frontrunner in commercial aviation, Airbus is spearheading the transition towards a greener future with resolute determination and strategic initiatives. Grounded in innovative technologies and a steadfast commitment to environmental stewardship, Airbus is driving significant reductions in emissions across the aviation value chain.

Setting a bold precedent, Airbus has pledged to achieve netzero carbon emissions for its commercial aviation division by 2050. This audacious target necessitates a comprehensive approach, and Airbus is embracing the challenge head-on.The cornerstone of Airbus’s sustainability strategy lies in the deployment of pioneering technologies and the adoption of cleaner fuel alternatives.

- Sustainable Aviation Fuel (SAF): Positioned at the forefront of sustainable aviation, Airbus champions the utilisation of SAF derived from renewable sources. By aiming for full certification of all commercial aircraft to operate on 100 per cent SAF by 2030, Airbus leads by example while actively promoting policies and collaborations to enhance SAF production and adoption.

- Hydrogen: Pioneering the Future of Flight: Beyond conventional alternatives, Airbus is revolutionising the industry with its ZEROe concept aircraft, powered by hydrogen fuel cells. This groundbreaking innovation is poised to realise the world’s first zero-emission commercial aircraft by 2035, supported by concerted efforts to develop essential infrastructure in collaboration with governments and research entities. In tandem with its pursuit of alternative fuels and groundbreaking designs, Airbus remains committed to optimising existing technologies to maximise efficiency.

- Fleet Renewal: Through continuous innovation, Airbus designs aircraft models that surpass their predecessors in fuel efficiency, ensuring a seamless transition towards cleaner technologies as airlines renew their fleets.

- Operational Enhancements: Recognising the significance of operational practices in emissions reduction, Airbus collaborates closely with stakeholders to develop strategies that minimise fuel consumption through optimised air traffic management and flight operations.

In its quest for sustainability, Airbus explores a spectrum of propulsion technologies, including hybrid and electric options for shorter-haul flights, promising further advancements in emissions and noise reduction. Adopting a holistic perspective, Airbus integrates sustainability throughout the lifecycle of its aircraft, from material sourcing to disposal, and actively engages in industry-wide initiatives to promote sustainable aviation practices.

CFM: SUSTAINABILITY GOALS AND THE RISE PROGRAMME

CFM International, a joint venture between GE and Safran, is dedicated to advancing sustainable aviation technologies. Their mission is clear: to mitigate the environmental impact of air travel by prioritising reductions in fuel consumption and carbon dioxide emissions. At the forefront of this endeavour lies the Revolutionary Innovation for Sustainable Engines (RISE) programme, a cornerstone of CFM’s sustainability strategy.

Launched in June 2021, the RISE programme is strategically crafted to foster the development and demonstration of nextgeneration engine technologies, each with ambitious environmental objectives. These objectives include a targeted 20 per cent enhancement in fuel efficiency and a corresponding reduction in CO2 emissions, aiming to significantly curtail greenhouse gas contributions to climate change.

Moreover, the RISE programme underscores CFM’s commitment to alternative energy compatibility, particularly with cleanerburning fuels such as Sustainable Aviation Fuel (SAF). Additionally, the programme explores the feasibility of utilising hydrogen as a sustainable aviation fuel source, setting a precedent for future industry practices. Technological innovation is the hallmark of the RISE programme, with a focus on cutting-edge advancements in materials, engine core design, and fan architecture. From the integration of Ceramic Matrix Composites (CMC) to the adoption of resin-transfer-moulded composite fan blades, each innovation contributes to enhanced efficiency and durability.

A standout feature of the RISE engine is its open-fan architecture, which allows for unprecedented airflow and bypass ratios, leading to improved propulsive efficiency and reduced fuel consumption. Beyond RISE, CFM maintains a holistic approach to sustainability, continually refining engine design, manufacturing processes, and maintenance practices to minimise environmental impact throughout the engine lifecycle.

The RISE programme epitomises CFM’s unwavering dedication to sustainability, marking a pivotal step towards a greener future for air travel. Through relentless innovation and a commitment to environmental stewardship, CFM aims to redefine the aviation landscape, paving the way for a more sustainable and eco-conscious industry.

GE AEROSPACE’S DEDICATION TO SUSTAINABLE AVIATION

GE Aerospace stands at the forefront of sustainable practices within the aviation sector, exemplifying a steadfast commitment to environmental stewardship. Central to their sustainability endeavours is the GE9X turbofan engine, emblematic of their pursuit of ambitious ecological objectives.

At the heart of GE’s sustainability journey lies the GE9X turbofan engine, heralded as the epitome of fuel efficiency in its class. Through groundbreaking engineering, it significantly diminishes both emissions and fuel consumption, underscoring a paradigm shift towards a more eco-conscious operational paradigm for airlines embracing this technology. Recognising the imperative of relentless innovation, GE ventures beyond the GE9X, delving into a spectrum of advanced technologies poised to define the future of aviation sustainability:

- Open Fan and Hybrid-Electric Propulsion Systems: GE spearheads initiatives such as the CFM RISE programme and collaborates with NASA on megawatt-class hybrid-electric propulsion systems, charting a course towards unprecedented fuel efficiency and emission reduction.

- Compact Engine Cores: GE’s pursuit of compact engine cores aims to optimise efficiency further, potentially facilitating the development of inherently sustainable aircraft configurations.

- Alternative Fuels: Acknowledging the constraints of conventional jet fuel, GE champions the adoption of sustainable aviation fuel (SAF) and hydrogen as viable alternatives, offering a pathway to drastically reduce carbon footprint and achieve emissions neutrality.

Embracing hydrogen as the ultimate frontier of sustainability, GE collaborates with industry leaders like Airbus and CFMI to conduct groundbreaking flight tests of hydrogen-powered engines, marking a pivotal milestone towards realising emission-free air travel. Also, recognising the transformative potential of digital tools, GE is poised to leverage data-driven solutions to optimise engine performance, streamline flight operations, and enhance maintenance practices, thereby contributing significantly to emissions reduction and fuel conservation industry-wide.

PRATT & WHITNEY CHAMPIONS SUSTAINABLE AVIATION WITH GTF INNOVATION

Responding to the urgent call for sustainable aviation solutions, Pratt & Whitney (P&W) is resolutely advancing a forward-looking strategy through their next-generation GTF (Geared Turbofan) engine technology. This proactive approach underscores their commitment to significant advancements in fuel efficiency and environmental stewardship within the aviation industry.

GTF – Revolutionising Aviation Efficiency:

- Fuel Efficiency Target: P&W aspires to achieve a minimum 10 per cent enhancement in fuel efficiency by the decade’s end, translating into substantial reductions in fuel consumption and carbon emissions.

- Enhanced Propulsive Efficiency: Central to the GTF plan is the expansion of fan diameter, facilitating a higher bypass ratio. This optimisation, targeting 14:1 compared to the current 12.5:1, ensures more effective engine power utilisation and reduced fuel consumption.

- Lightweight Construction: P&W is poised to introduce a 3D-woven composite fan, replacing conventional aluminium and titanium counterparts. This innovation promises a significant reduction in fan weight, thereby enhancing overall engine efficiency.

- Advanced Gear System: The GTF blueprint integrates an optimised fan-drive system gear ratio, enabling the engine to operate at peak efficiency, thereby further reducing fuel consumption.

P&W envisages up to a 5 per cent thrust increase in select engines by strategically elevating internal operating temperatures. To ensure safe operation under heightened thermal stress, the GTF programme incorporates cutting-edge advancements:

- High-Temperature Materials: Adoption of advanced materials like metal superalloys, Ceramic Matrix Composites (CMCs), and carbon-based materials fortifies the engine against heightened thermal stress.

- Intelligent Cooling Systems: P&W is pioneering intelligent cooling systems that deliver precise cooling air to engine blades throughout the flight cycle, optimising engine performance while curbing energy consumption for cooling.

Pratt & Whitney’s GTF technology blueprint epitomises a steadfast dedication to sustainable aviation. By prioritising fuel efficiency, emission reduction, and thrust augmentation, P&W emerges as a vanguard in forging environmentally conscious propulsion systems for the aviation industry’s future.

ROLLS-ROYCE: PIONEERING SUSTAINABLE AVIATION

Rolls-Royce is not merely advancing engine technology; they’re shaping the future of aviation with sustainability at its core. Their ambitious objectives target achieving net-zero carbon emissions across their operations by 2030 and extending this impact to the sectors they serve by 2050. A testament to this commitment is the groundbreaking UltraFan programme.

The UltraFan engine stands as a testament to innovation. Boasting a record-breaking 140-inch fan diameter, it not only claims the title of the world’s largest engine but also prioritises Sustainable Aviation Fuel (SAF). Its inaugural ground test in May 2023, fuelled entirely by SAF, underscores its dedication to cleaner skies.

Rolls-Royce proudly declares that the UltraFan isn’t just the quietest engine ever built but also the most fuel-efficient, offering a remarkable 25 per cent improvement in fuel burn compared to its predecessor, the Trent XWB. This translates to substantial reductions in CO2 emissions, addressing a critical aspect of climate change.

Expected to be commercially available by 2030, the UltraFan represents a significant stride towards sustainable aviation, positioning Rolls-Royce as a frontrunner in fostering a greener future for air travel. The UltraFan programme is just one facet of Rolls-Royce’s sustainability initiative. They are actively pursuing:

- 100 per cent SAF Compatibility: Committing to prove compatibility of all current Trent and Business Aviation engines with 100 per cent SAF by the end of 2023.

- Net Zero Products: Ensuring new Rolls-Royce products are geared for net-zero operation by 2030, with all products achieving this milestone by 2050.

Through a dedicated focus on cleaner technology and responsible fuel usage, Rolls-Royce demonstrates unwavering dedication to a sustainable future for air travel. The UltraFan programme epitomises how innovation can catalyse positive environmental change.

ADVANCING ELECTRIC AND HYBRID-ELECTRIC AVIATION

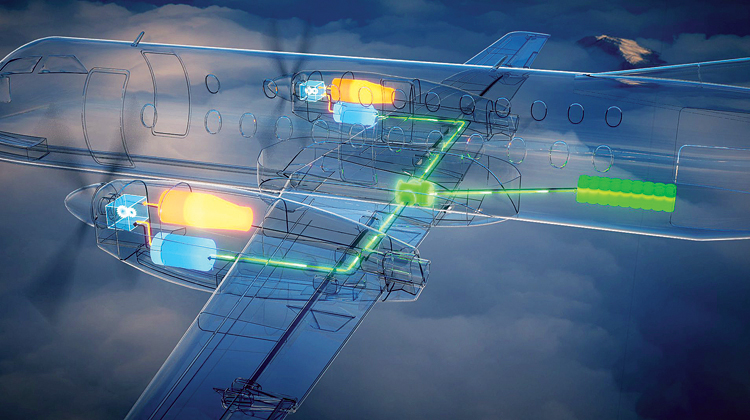

The aviation sector is experiencing remarkable advancements in alternative propulsion systems, notably electric and hybrid-electric technologies. While electric aircraft contend with range limitations compared to conventional jet fuel, hybrid-electric setups present a viable solution by harnessing the strengths of both energy sources. These systems optimise energy efficiency and diminish fuel consumption by integrating a blend of jet fuel and electricity.

Recent collaborations, such as those between GE and NASA, have conducted pioneering tests on hybrid-electric propulsion systems, aiming to bolster performance at high altitudes. Furthermore, initiatives like the Sustainable Water-Injecting Turbofan Comprising Hybrid-Electrics (SWITCH) project, funded by the European Union, are propelling technologies like water-enhanced turbofans and hybrid-electric systems forward, promising substantial enhancements in fuel efficiency and emissions reduction.

Hydrogen emerges as another promising power source for aviation, offering superior energy density and emitting zero CO2 when derived from renewable sources. Airbus, in conjunction with partners like ArianeGroup, is spearheading hydrogenbased propulsion technologies, including hydrogen combustion and fuel cells, through its ZEROe concept. Similarly, startups like ZeroAvia and Universal Hydrogen are making significant progress with fuel cell-powered aircraft, heralding a more sustainable future for short-haul flights.

As the sector explores various propulsion alternatives, the shift towards renewable power sources underscores the imperative for green energy production methods to achieve substantial environmental advantages.