Role of Pratt & Whitney in Mainstream Air Transport

Pratt & Whitney (P&W) is a subsidiary of United Technologies Corporation (UTC) producing aircraft engines widely used in both civil and military aviation

Pratt & Whitney (P&W) Aircraft Company was set up in 1925 in the United States (US) and, in the same year, its first aircraft engine, the R-1340 Wasp, was ready to make a spectacular entry into American aviation. A whole series of Wasp engines followed and were remarkably successful in the years to come. Several more engines have been added to P&W’s repertoire since then. In 1929, P&W Aircraft merged with Boeing et al to form the United Aircraft and Transport Corporation (UATC) while retaining its P&W name. In 1934, the US government banned common ownership of airplane manufacturers and airlines. Consequently, P&W was merged with UATC’s other manufacturing interests as United Aircraft Corporation which was later reorganised in 1975, as United Technologies Corporation (UTC), headquartered in Farmington, Connecticut. UTC carries out research, develops and manufactures products in a number of areas including aircraft engines, aerospace systems, Heating Ventilation and Air Conditioning, elevators and escalators, fire and security, building systems and industrial products. P&W is now a subsidiary of UTC, producing aircraft engines widely used in both civil and military aviation and today, the company is one of the major players in the market. P&W Canada is an aero-engine manufacturing division of P&W located in Longueil in Quebec in Canada. While P&W develops and manufactures large engines, P&W Canada has the responsibility for small and medium ones.

COMMERCIAL AIRLINERS

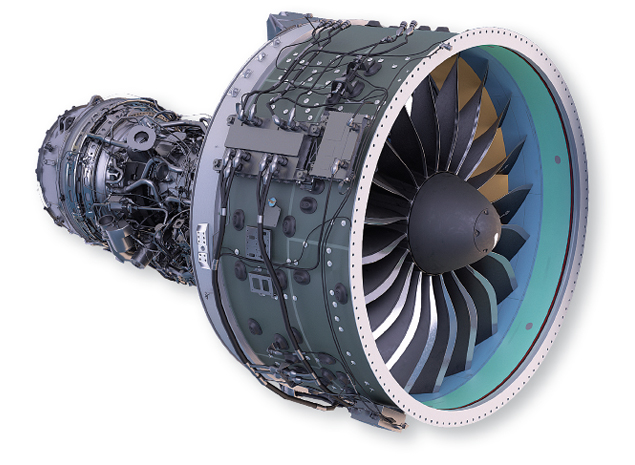

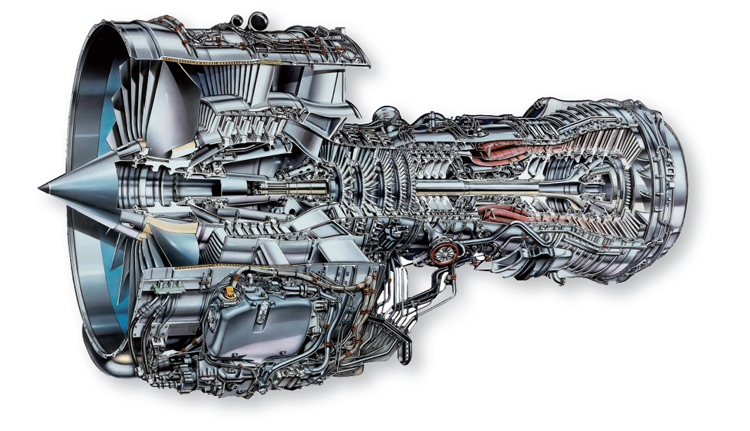

P&W claims that its fleet of commercial engines has logged over a billion hours of flight time on narrow and wide-body commercial airliners carrying passengers and cargo. The pride of place in P&W’s psyche is reserved for the Geared Turbofan, officially abbreviated by P&W as GTF, line of engines. While in a conventional turbofan engine, the fan, the Low Pressure (LP) compressor and the LP turbine are all mounted on a single shaft, in a GTF engine, the fan is connected to the LP shaft using a reduction gearbox thus permitting the fan to run at a lower rotational speed than the LP shaft. This design has the advantage of enabling fewer stages of LP compressor and turbine as these can now run at a higher rotational speed than the erstwhile speed where the coaxial fan’s tip speed became a limiting factor due to its larger radius. The design produces much less noise and reduces fuel consumption. Catering to the 14,000 to 33,000 lbs of thrust range, GTF engines power five aircraft families namely Airbus A220 (PW1500G), Airbus A320neo family (PW1100G-JM), Embraer E190-E2 (PW1700G), Mitsubishi Regional Jet (MRJ) (PW1200G) and Irkut MC-21 (PW1400G-JM). The first GTF engine to enter commercial service was the PW1100G-JM in 2016 and, according to P&W, the GTFpowered A320neo has achieved a 16 per cent reduction in fuel consumption, 75 per cent reduction in noise footprint and 50 per cent reduction in NO2 emissions. Lamentably, its record on the A320neo family has been fraught with safety and maintenance woes, detracting somewhat from the GTF sheen.

P&W CLAIMS THAT ITS FLEET OF COMMERCIAL ENGINES HAS LOGGED OVER A BILLION HOURS OF FLIGHT TIME ON NARROW AND WIDE-BODY COMMERCIAL AIRLINERS

The V2500 engine is another P&W steed designed and manufactured by P&W in partnership with Japanese Aero Engine Corporation and MTU Aero Engines, as a global partnership called International Aero Engines. The engine powers Airbus A319, A320, A321 and the Boeing MD-90. Another version is available for military use as V2500-E5 that powers the Embraer KC-390.

The GP7200 is a twin-spool axial flow turbofan engine that delivers 70,000 lbs of thrust and powers the Airbus A380. The design was a result of collaboration between P&W and GE as Engine Alliance, a 50/50 joint venture between the two entities. It was established in 1996, specifically for developing, manufacturing, selling and supporting a family of advanced technology engines for new high-capacity, long-range aircraft. The GP7200 was a result of amalgamating two of the most successful wide-body engine programmes in aviation history-the PW4000 and GE90. It entered service in 2008, with the world’s largest A380 fleet, Emirates and was followed by GP7200 for the A380 fleet of Air France.

The PW4000-94, named thus because of its 94-inch fan, was the first model in the PW4000 family of high thrust engines covering a range of 52,000 to 62,000 lbs of thrust and powers five major aircraft namely the Boeing 747 and 767, the Airbus A300, the A310 and the MD-11. It has been powering airliners since 1987, and continues to provide excellent service. Developed specifically for the Airbus A330 twinjet and introduced in 1994, the PW4000-100 with a 100-inch fan, produces 64,500 to 70,000 lbs thrust at take-off. The engine was the first in aviation history to qualify for Extended-range Twin-engine Operations (ETOPS) prior to entering service and is currently approved for 180-minute ETOPS.

P&W has introduced the PW4170 Advantage70 programme which is offered as a new engine and as an upgrade kit for existing engines. Advantage70 technology delivers superior engine performance, including a two per cent thrust increase, more than one per cent reduction in fuel consumption, increased durability and reduced maintenance costs. The PW4000-112 is a 74,000 to 90,000 lbs thrust engine used in Boeing 777 family of aircraft. The PW2000 engine powers all models of Boeing 757 and produces 37,000 to 43,000 lbs thrust while the PW6000 is an 18,000-24,000 lbs thrust engine designed for 100 passenger aircraft and currently powers the Airbus A318.

THE MAJOR ENGINE MANUFACTURERS IN THE WORLD ARE COMMITTED TO MAKING SIZEABLE INVESTMENTS IN R&D IN ORDER TO DEVELOP HIGH QUALITY PRODUCTS

Older engines include the JT8D introduced in 1964 with the Boeing 727-100 aircraft. It has eight models producing thrust between 14,000 and 17,000 lbs. The later JT8D-200 series was introduced in 1980 with a thrust of 18,500 to 21,700 lbs and powers the MD-80 series of aircraft. The JT9D entered service on the Boeing 747 in 1970 and went on to be used on Boeing 767, Airbus A300, A310 and DC-10 aircraft. There are three series of the engine covering the range of 46,300 lbs to 56,000 lbs thrust. Constant upgrades and modifications continue to be introduced by P&W to improve durability and on-wing time, increase thrust and reduce noise and emissions.

REGIONAL AND BUSINESS AIRCRAFT

As mentioned earlier, the small and medium range of aircraft engines are the responsibility of P&W Canada which, while being a division of P&W, is independent in terms of R&D and marketing. As far as regional aviation is concerned, P&W claims to have invented the segment. At the moment, its PW100 and PW150 turboprop engines in five series (38 models) ranging in power from 1,800 to 5,000 shaft horse power (shp) provide power for around 3,500 aircraft of 18 types globally. P&WC is reportedly working on a Next Generation Regional Turboprop (NGRT) engine for a 70-to-90 seat aircraft which it claims will be 20 per cent more efficient than existing engines with a 20 per cent reduction in maintenance costs. The new engine is scalable from 4,500 to 8,000 shp and is likely to be ready by 2025.

In the domain of business aviation, P&W has a wide range of engines to offer. The PW300 is a 4,700 to 8,000 lbs thrust engine in 13 models which are fitted on ten types of aircraft. The PW500 is installed on seven types of aircraft and covers the 2,900 to 4,500 lbs thrust range. The PW600 lies in the 300 to 9,000 lbs thrust range and powers three types of aircraft. The PW800 family is a turbofan engine in the 10,000–20,000 lbs thrust class intended for the regional jet and business jet market. In October 2014, P&WC announced that the new Gulfstream G500 and G600, both clean sheet business jets, launched by GAC, would be powered by PW800 engines. A unique feature of the G500 and G600 engines is that they will not be needing P&WC’s Flight Acquisition Storage And Transmission (FAST) engine monitoring system, as the aircraft can transmit their engine sensor data consisting of 300 parameters through their own systems. G500 and G600 aircraft will downlink to the FAST ground stations to relay full flight data consisting of more than 300 parameters.

CONCLUDING REMARKS

According to Aircraft Turbofan Engine Market Research Report 2018 published by Market Research Future, the top four market players are CFM (with an estimated 35 per cent market share), P&W (21 per cent), Rolls-Royce (18.5 per cent) and GE (18.3 per cent). Apart from being among the four market leaders, P&W is also a part of joint ventures. Engine Alliance is a 50/50 joint venture between General Electric and P&W formed in August 1996, to develop, manufacture, sell and support a family of modern technology aero engines for new high-capacity, long-range aircraft while International Aero Engines is a Zürich-registered joint venture between P&W, MTU Aero Engines and Japanese Aero Engine Corporation. The collaboration has produced the V2500, the second most successful commercial jet engine programme in production today in terms of volume.

The major engine manufacturers mentioned above are committed to making sizeable investments in R&D in order to develop high quality products and, despite advances made in electric/hybrid propulsion, the market for next-generation turbofan engines is expected to be highly lucrative during the coming decade or so. Use of bio-fuels to address environmental concerns is part of the ongoing R&D to design engines that can embrace bio-fuels in the future. P&W appears all set to ride the market as a major and prominent player.