Jets vs Turboprops

When it comes to performance, both jet and turboprop aircraft in the regime of business aviation have attributes and limitations that a prospective buyer would need to take into account while selecting and evaluating the platform

An issue that plagues the minds of those who are new to the field of aviation is often related to choice of aircraft powered by jet engines as against one powered by a turboprop engine. Essentially, the issue boils down the type of power plant the aircraft in question is equipped with.

History of Development of Engine Technology

A jet engine, also referred to as ‘turbojet’, represents a quantum jump in technology over the piston engine, which was the only power plant for aeroplanes till the end of World War II. The turbojet is an air breathing, gas turbine engine that has an internal combustion cycle during its operation. The credit for the invention of the jet engine, a feat that was achieved just before World War II, goes to Sir Frank Whittle who worked on this project single-handedly and had patented the concept in 1930. Sir Frank Whittle, regarded as the father of the modern turbojet engine, was an engineer in the British Royal Air Force and retired from service in 1948 in the rank of Air Commodore. A few years after the success recorded by Sir Frank Whittle, Hans Von Ohain, an aeronautical engineer in Germany, came up with a design that evolved into the first operational jet engine. Soon after, in 1938, a little-known Hungarian aeronautical engineer named György Jendrassik, came up with a design of the first true turboprop (short for turbo propeller) engine, designated the Cs1. Throughout the period of World War II, technological innovations in aircraft engines continued to take place.

THE CHOICE OF JET OR TURBOPROP AIRCRAFT BY THE AIRLINE INDUSTRY IS INFLUENCED LARGELY BY THE ECONOMICS OF THEIR BUSINESS MODELS

However, it was the turbojet and not so much the turboprop engine that was generally regarded as a significant advancement in technology in the domain of power plants for aircraft. The airframe platforms for testing turbojet engines under development were produced by Heinkel Flugzeugwerke in Germany and the Gloster Aircraft Company in Britain. However, it was only after World War II that the jet engine became a widely used as the power plant for aeroplanes.

Design Features

Turbojet Engine. A turbojet is essentially an internal combustion, air breathing engine with a rotating air compressor laid out in several stages and mounted on the drive shaft. Cold air from the atmosphere is drawn into the engine through the air intake and by means of the rotating compressor blades, the mass of air is compressed to high pressure as much as 10 times the normal atmospheric pressure, as it passes through the stages of the axial flow compressor and is mixed with fuel. The fuel and air mixture then is ignited in the combustion chamber and the rapidly expanding hot gasses exit the rear end of the engine where the exhaust is located, imparting the engine and in turn the aircraft on which it is mounted, substantial reactionary forward thrust which propels the aeroplane forward.

THE TWO ARE MUTUALLY COMPLEMENTARY AS EACH ONE TAKES CARE OF A SEGMENT OF THE INDUSTRY THAT THE OTHER IS NOT BETTER EQUIPPED TO DO SO

Turboprop Engine. The turboprop engine is an advancement in design over the turbojet engine around which it is engineered. Essentially, the energy generated by the combustion of the fuel and air mixture as in the turbojet engine is used to impart rotation to the drive shaft which through a reduction gear mechanism, drives a multi-blade propeller mounted at the front end of the drive shaft. The forward thrust is generated by the mass of air propelled rearwards by the propeller. Thus the turboprop engine is a hybrid between two designs as it combines a jet engine with a constant speed, variable pitch propeller that was developed as a part of the large or high powered piston engines.

Jet or Turboprop Aircraft in Business Aviation

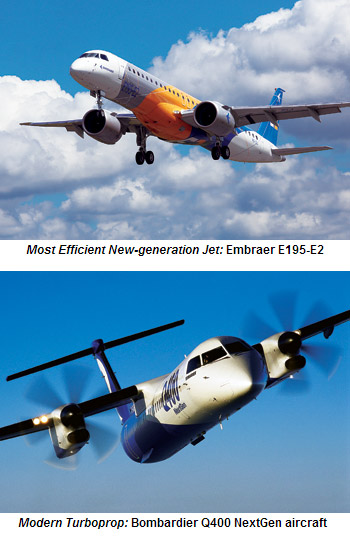

When it comes to performance, both jet and turboprop aircraft in the regime of business aviation have attributes and limitations that a prospective buyer would need to take into account while selecting and evaluating the platform. An important characteristic of turboprop powered aircraft is that it is designed to fly at medium speeds at which it delivers the most optimum performance in terms of economy in operations. This is because the efficiency of a propeller is the highest at a particular speed in the medium speed range. The propeller is efficient at flight speeds below 725 kmph. However, the efficiency of the propeller reduces with increase in speed beyond the design parameters. Turbojets on the other hand are relatively much less efficient at low speeds and their efficiency improves significantly in a speed range that is higher than aircraft that are powered by of turboprop engines.

One advantage that the turboprop aircraft offers is that it is generally more capable of operating from grass airfields. Jet aircraft on the other hand, require a concrete runway for take-off and landing. Turboprop aircraft are also capable of operating from smaller airstrips as compared to jet aircraft of similar size and class. This is particularly relevant for business houses whose executives need to visit cities and towns that have smaller airports. Just as an example to illustrate this point, a King Air 250 turboprop aircraft can operate from a 2,400 feet runway whereas a Citation CJ4 business jet requires a much longer runway, one that is 3,410 feet in length.

From the point of view of passenger comfort, while jet engines have higher noise levels, turboprop aircraft are less noisy; but may have slightly higher vibration levels. However, in modern turboprop business aircraft, vibration levels are generally within tolerable limits. Modern twin-turboprop aircraft are as comfortable and well equipped as business jets of the same category.

From the financial perspective, turboprop aircraft have a lower cost of operation as compared to business jets of the same class. For flying in sectors where distances to be flown are short, the disadvantage of turboprop aircraft in terms of time taken to reach the destination on account of its lower cruising speed compared to jet aircraft, is negligible. However, the cost savings with the turboprop aircraft are high. Just to illustrate, for a distance of up to 400 nautical miles, cost saving on fuel with an Avanti is around $195 per hour as compared to a Cessna Citation CJ3 business jet. The single-engine turboprop business aircraft are also extremely comfortable and have lower operating costs on account of the fact that they only have one engine resulting in lower maintenance costs compared to twin-engine aircraft. Some other expenses such as maintenance costs per flight hour and perhaps insurance, tend to also be lower for turboprops.

The two companies of global fame manufacturing engines for turboprop aircraft are Pratt & Whitney Canada whose main product is the PT6A and is variants that are used widely on several platforms across the world. The other engine manufacturer is Honeywell Aerospace whose product TPE 331 and its variants are also fitted on a number of turboprop aircraft used in business aviation. Both these products have built up a consistent reputation for reliability and are fitted not only business aircraft, but also on military, agricultural and small aircraft used by the airline industry.

Jet or Turboprop in the Airline Industry

The choice of jet or turboprop aircraft by the airline industry is influenced largely by the economics of their business models. As airliners powered by two or four jet engines are generally of large size, fly at close to supersonic speeds at altitudes between 35,000 feet and 40,000 feet and carry large passenger and cargo loads, these offer better economy of operations when deployed for long distance flights both within the country or across the oceans to other continents. Compared to jet engine powered airliners, aircraft equipped with turboprop power plants are smaller in size and have lower seating capacity generally under 100. As these aircraft operate between altitudes of 20,000 feet and 25,000 feet as also have lower range and endurance capability, these are better suited for operations over short distances as these aircraft provide far better economy of operations. It should be obvious as to why turboprop airliners such as the ATR and the Q400 dominate regional aviation.

The Final Word

The expression Jet vs Turboprop in the title of this article is likely create an impression that these two segments of the airline or business aviation fleets are rivals and are competing against each other in the aviation industry. The fact of the matter is that this is not the case. In fact the two are mutually complementary as each one takes care of a segment of the industry that the other is not better equipped to do so. While rapid technological advancements are taking place in both the sectors, there is no possibility whatsoever of either one displacing or replacing the other.