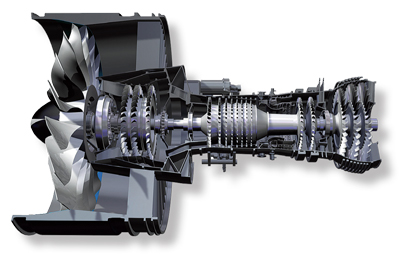

Pratt & Whitney PurePower Engines

The Pratt & Whitney PurePower Geared Turbofan Engine introduced dramatic improvements in propulsive efficiency and noise reduction

Pratt & Whitney PurePower Engines comprise two aero-engine families, the PW800 engine family and the PW1000G or Geared Turbo Fan (GTF) engine family. Common between the PW800 and PW1000G engine families is the PurePower engine core which is a high-performance core built for the demands of high-cycle, short-haul operation.

FAMILY CORE

It is a state-of-the-art engine-core that is fully capable from 10,000 to 40,000 pounds of thrust. Scaling the engine core over this range had been enabled by the GTF engine architecture. GTF engines can slow the fan rotation while greatly increasing the speed of the low-pressure modules, the Low-Pressure Compressor (LPC) is able to “supercharge” the air before it enters the High-Pressure Compressor (HPC). In turn, that means fewer HPC stages are required to achieve the same level of performance. The end result for operators is that lighter-weight core with fewer parts, which is easier to maintain, with hundreds fewer aerofoils and fewer Life-limited Parts (LLPs) are required. All this with the same core across two families of engines gives operators the benefit of higher maturity that comes with many hours of operations. The GTF family offers double-digit improvements in fuel consumption, noise, environmental emissions and operating costs. The GTF-powered A320neo provides 16 per cent better fuel efficiency from prior-generation engines, 75 per cent reduction in noise footprint and a 50 per cent reduction in regulated emissions.

Over 50 operators across the globe have installed GTF engines on 875 planes in the five years since the new technology became available. With engine options ranging from 14,000 pounds of thrust to 33,000 pounds, GTF has become a source of propulsion on five families of aircraft, including both the Airbus A220 ( formerly Bombardier’s C-Series) and the A320. Pratt & Whitney’s website says a GTF engine takes off somewhere around the world every 30 seconds and while that number may have been reduced by the COVID-19 Pandemic, it is worth noting that 80 per cent of the A320 fleet which carries most of the installed GTF engines, has already returned to service. Pratt & Whitney has orders and/or commitments in hand for 10,000 Geared Turbofans and these numbers are likely to rise fast as the Pandemic recedes. This is just the beginning for the Geared Turbofan. In the future, Pratt & Whitney will, in all likelihood, make additional gains in thermal efficiency, application of advanced materials and other engine features as it scales up the technology for larger aircraft. The after-sales service is enabled by the latest advances in engine health management and advanced analytics with support delivered through a global network and local representatives. The next-generation data acquisition and predictive analytics tools, eFAST™ technology, enable them to help predict and prevent future maintenance issues. There are 18 MRO centres worldwide that are supported by over 150 dedicated field representatives.

TEETHING ISSUES

Two sets of issues were faced on these engines. First was the response of other engine parameters, components and control systems to the new variable fan speed. Second was the new mechanical stresses that the gearing mechanism generates. The new stresses especially affected the low-pressure compressor and turbine, leakages in the air seal in the third bearing and heightened wear on the turbine. A re-designed piston seal in the high-pressure compressor has been introduced to address the concern of transient vibration.

It is a state-of-the-art engine-core that is fully capable from 10,000 to 40,000 pounds of thrust

At present, apart from the various modified seals and bearing dampers, a modified main gearbox has been made mandatory along with a modified third-stage low-pressure turbine. In addition, no engine that has been removed is accepted back from overhaul/maintenance without these. Pratt & Whitney has tied up with Air India Engineering Services Ltd. (AIESL) to maintain the PW1100GJM engines at its facility in Mumbai.

EXTENDED DIVERSION TIME OPERATIONS (EDTO)

The Pratt & Whitney engines suffered multiple malfunctions which led to in-flight shutdowns. This forced the Directorate General of Civil Aviation (DGCA) to restrict EDTO operations of A320 and A321Neo aircraft, primarily operated by IndiGo and GoAir. Restrictions on EDTO meant that these two carriers were forced to use older A320 CEO aircraft that consume more fuel or take a longer route to destinations such as Kuala Lumpur, Singapore, Bangkok, Phuket and Muscat, which extend beyond the 60-minute flight range from the nearest alternative airport. The approval for EDTO operations comes after IndiGo has successfully completed mandatory replacement of P&W engines turbine blades built with titanium with sturdier engine turbine blades made with a nickel-chromium alloy before the August 31, 2020, deadline set by the aviation regulator.

IndiGo had also been asked to modify its take-off practice of using maximum thrust, which exerts greater stress on the turbines, with the airline recording more turbine failures than other carriers. GoAir, on the other hand, used a gentler lower-thrust socalled “alt-climb” approach. While IndiGo’s approach may use less fuel, it has its side effects. Due to the glitches, IndiGo, in 2019, had decided to switch from PW engines, placing a $20 billion order instead with rival CFM, a venture between General Electric Co and France’s Safran SA.

COMPOSITES IN PERFORMANCE ENHANCEMENT

The Pratt & Whitney PurePower Geared Turbofan Engine introduced dramatic improvements in propulsive efficiency and noise reduction. To continue improving the overall efficiency of engines, further improvements to thermal efficiency have been targeted. Ceramic Matrix Composites (CMCs) is one technology that offers significant promise. The higher operating temperature of CMCs compared to current state-of-the-art single crystal castings, will enable the reduction or elimination of component cooling air and may also enable higher combustion temperatures thereby increasing thermal efficiency. While CMCs offer tremendous promise, the cost of CMCs is a significant challenge.

Notably, Pratt & Whitney introduced the PW1000G geared turbofan engine family without CMCs, using instead single-crystal nickel alloys and advanced Thermal Barrier Coatings (TBC). CMCs with advanced TBC, also called Environmental Barrier Coatings, or EBCs, offer a significant improvement. Could the CMC aerofoils which are to be produced in Pratt & Whitney’s new Asheville plant debut on a PW1000G upgrade in development for the Airbus A321XLR? Announced in June 2019, The XLR is a stretched version of the A321 that offers 15 per cent more range than the previous stretched model and 30 per cent lower fuel burn. According to Pratt & Whitney, its aerofoil facility in Asheville will create 800 new jobs through 2027 in Buncombe County. The new, state-of-the-art facility will implement best-in-class manufacturing technologies and processes embodying industry 4.0 manufacturing principles and will complement existing turbine aerofoil work that is done across Pratt & Whitney’s facilities.